We provide excellent service support & our team of engineers studies the requirement of the customer & we try to resolve the issue at due course of time

We offer annual maintenance service for various equipments to avoid breakdown & save your valuable time ,money.

We offer service for the following equipments

Just as your car requires a yearly service and mot check so does your CMM. Due to environmental factors and excessive use your coordinate measuring machine can and will occasionally have it’s accuracy compromised. To maintain accuracy prior to impacting on your production and manufacturing it is recommended your CMM is serviced and verified regularly.

We do service & retrofit of CMM with spares support.

Servicing of Profile projector ,retrofit,Upgradation of the panels ,scales. With cost effective solution.

Servicing & Calibration of Video Measuring machines with error correction ,Spares support for various makes.

We provide Excellent service , calibration support for 2D Microhite & TESAHITE with spares support.

Autonomous instruments for measurement in one or two coordinate directions of inside dimensions, outside, tiered, height, depth and distance on geometric elements with flat, parallel or cylindrical surfaces. The cusp is automatically entered on the bores and shafts - With memory function "max", "min" and "max-min" as dynamic measurement.

The metrology-based reference for the workshop Stand-alone design – Made to measure any size in in the form of internal, external, height, depth, step and distance dimensions of geometric part features having either a flat, parallel or cylindrical surface.

Automatic capture of the culmination point on bores or shafts – Dynamic probing with memory functions <<max.>>, <<min.>> plus <<max.-min.>> • State-of-the-art concept associated with a high-quality design is the fruit of years of experience in the manufacture of electronic height gauges.

Today in market we have considerable amount of Tesa machines for service ,with our experienced team we provide good service & tap various locations around INDIA. This makes SPARX one stop Shop for quality & SERVICE .

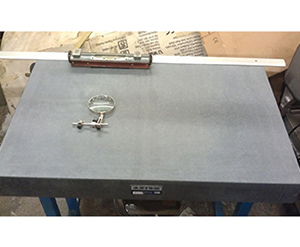

We are doing relapping of Granite Surface Plate to Grade 0 accuracy as per IS 7327-2003.We supply a wide range of surface plates, which are used in various industries for tool making, inspection, spotting, gauging etc. Highly durable, reliable, resistant to corrosion and are easy to maintain, these surface plate make an ideal base for mounting sophisticated mechanical, electronic and optical gauging systems.

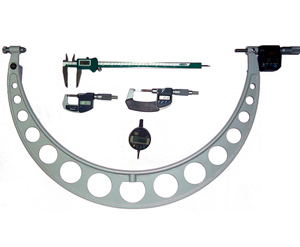

What is calibration and why do we need it ?

Calibration is a set of operations that under certain conditions establish relations between values indicated by a measuring instrument or system, or values represented by a materialised measure or reference material, and values realised by measurement standards. It is, however, less clear to everyone that a measuring instrument, too, needs maintenance, servicing, technical examination, etc., even if it is not broken.

So avoid this the instruments has to calibrated periodically to retain the accuracy , which inturn increases your productivity.We provide service support for Various measuring instruments & Testers.